15MH -Nonmagnetic high hardness material-

Our original material ‘15MH’:Non-magnetic and high hardness material

15MH has Non-magnetic, Corrosion resistance, Abrasion resistance characteristics.

Please contact us if you need more details.

15MH Characteristic

| Non magnetic | Magnetic permeability Under1.01μ Prevent from becoming magnetized and adhering among metals. |

| High hardness | Surfece hardness HV500 For rotary shaft and revolving shaft which require Abrasion resistance. Possible HV700 with our original process. |

| Corrosion resistance | Same as SUS304 For using out of doors and seaside which require Corrosion. |

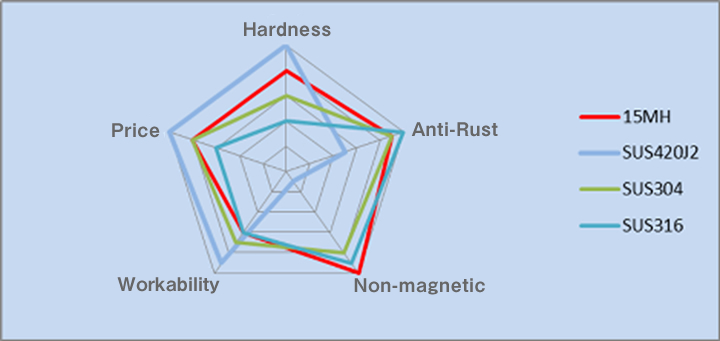

Comparison chart with other metal

Component, Mechanical properties and physical properties

Table of component

| Material | C | Si | Mn | P | S | Ni | Cr | Mo | N |

| 15MH | 0.05~0.25 | Under1.00 | 9.00~16.00 | Under0.060 | Under0.030 | 1.00~6.00 | 16.00~19.00 | - | 0.20~0.40 |

| SUS304 | Under0.08 | Under1.00 | Under2.00 | Under0.045 | Under0.030 | 8.00~10.50 | 18.00~20.00 | - | - |

| SUS316 | Under0.08 | Under1.00 | Under2.00 | Under0.045 | Under0.030 | 10.00~14.00 | 16.0s0~18.00 | 2.00~3.00 | - |

| SUS420J2 | 0.26~0.40 | Under1.00 | Under1.00 | Under0.045 | Under0.030 | Under0.06 | 12.00~14.00 | - | - |

Mechanical properties and physical properties

| Material | Hardness HV |

Density g/cm3 |

Longitudinal elastic modulus ×104N/mm2 |

Specific heat J/(g・k) |

Heat conductivity W/(m・k) |

Heat expansion coefficient ×10-6/℃ |

Electrical resistivity |

Magnetic permeability |

| 15MH | 500 | 7.75 | 19.5 | 0.46 | 14.7 | 13.1 | 70 | Non magnetic |

| SUS304 | Under200 | 7.93 | 19.3 | 0.59 | 16.3 | 16.1 | 72 | Non magnetic |

| SUS316 | Under200 | 8.03 | 19.3 | 0.50 | 15.2 | 17.3 | 74 | Non magnetic |

| SUS420J2 | 500~700 | 7.75 | 20.6 | 0.46 | 25.0 | 10.4 | 56 | Hard magnetism |

15MH processing specifications

| We introduce an example of processing results. | ||

Size |

||

|

||

|

・Regarding the shape, composite processing such as long hole (about 10 times the diameter), sideways hole, milling cutter, step, groove, D cut etc is possible. ・We will also consider other processing at any time. ・Grinding is also possible according to required accuracy. |

||

15 MH is a material with high processing difficulty, but our company can grinding and turning with high accuracy as well as other materials.

Moreover, we also correspond to D cut · both sides D cut.

For shafts, pins and precision rollers at 15 MH, please refer to here for possible specs.