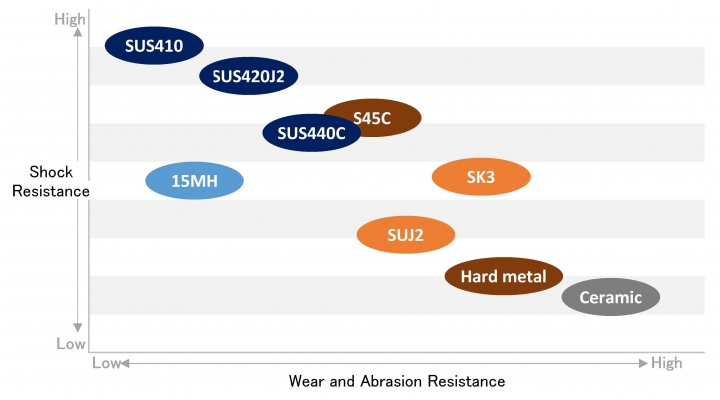

Wear and Abrasion Resistance

As a highly wear-resistant material , in the iron-based there is a carbon steel and alloy steel .

In a more highly wear-resistant material there is a ceramic or cemented carbide .

Please choose the material considering the balance of wear resistance and impact resistance.

Wear and abrasion resistance and Shock resistance

※Of stainless steel SUS440C is has excellent wear resistance , but is an expensive material.

Please try a low value material KWS4MA with excellent sliding properties in SUS440C equivalent hardness .

The above graph shows the impact resistance and abrasion resistance of the image.

Mechanical properties and physical properties (common temperature)

| Material | Hardness HV |

Density g/cm3 |

Longitudinal elastic modulus ×104N/mm2 |

Specific heat J/(g・k) |

Heat conductivity W/(m・k) |

Heat expansion coefficient ×10-6/℃ |

Electrical resistivity |

Magnetic permeability |

| SUS410 | 400~600 | 7.75 | 20.2 | 0.46 | 23.8 | 9.9 | 57 | Hard magnetism |

| SUS420J2 | 500~700 | 7.75 | 20.6 | 0.46 | 25.0 | 10.4 | 56 | Hard magnetism |

| SUS440C | 600~800 | 7.75 | 20.5 | 0.46 | 24.2 | 10.6 | 60 | Hard magnetism |

| KWS4MA | 600~800 | 7.75 | 20.6 | 0.46 | 24.7 | 10.6 | 67 | Hard magnetism |

| SUJ2 | 750 | 7.75 | 20.8 | 0.46 | 46.0 | 12.5 | Hard magnetism | |

| SK105(SK3) | 7.75 | 0.46 | 45.2 | 11.3 | Hard magnetism | |||

| Zirconium | 6.00 | 21 | 4.0 | 10.0 | Non magnetic | |||